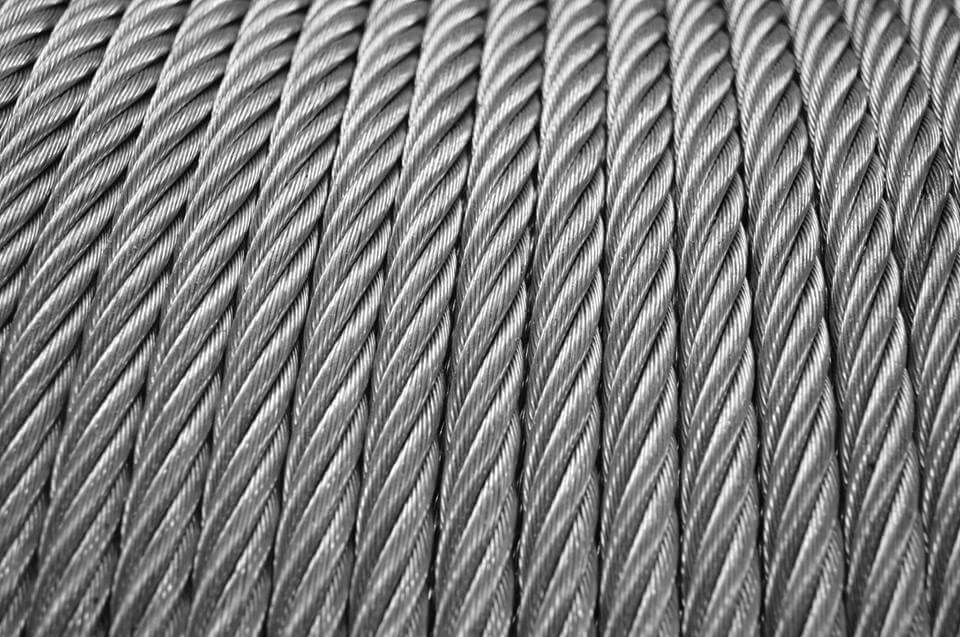

SYNTHETIC VS WIRE WINCHLINE ROPE

If you’re in the market for new rope for your winchline, but not sure about whether you need synthetic or wire rope, here’s a comparison.

Abrasion/cut resistance

Synthetic rope is more prone to damage on sharp edges and rough surfaces than wire rope. Wire rope is more resistant but will still be damaged by this. You can use protective sleeves on synthetic rope to help reduce wear and tear, just make sure not to wind the protective cover back inside the winch. Synthetic rope is also prone to collect small debris and dirt which can damage the rope from inside the strands.

Water

Synthetic rope is much lighter than wire and some types will float on water. Good quality synthetic rope doesn’t absorb water, won’t rust but can freeze in cold conditions. Wire rope is much heavier, will sink in water and over time will rust.

Weight

Synthetic rope is 8 times lighter than wire rope, reducing manual handling issues. Wire rope is heavier and stiffer to move than synthetic.

Synthetic rope 12 strand 12mm @ 100mtr = 7.8kg

Wire rope 12mm 6x36 @ 100mtr = 60.2kg

Longevity

Depending on the application, how it’s handled and looked after will affect the lifespan of your rope.

Field repairs

It’s commonly thought that it’s not possible to fix a broken wire rope in the field. However, with a bit of ‘bush mechanics’ it is actually possible to repair both types of rope. Depending on the condition of the remainder of the rope there is usually a reduced working load. A variation of the flemish splice can be used on wire rope for temporary repairs. This method has been used in the forestry and offshore industries for many years. To repair synthetic rope you can use a hand splice. Both repair methods are possible in the field but can be difficult without the correct tools and take skill and knowledge to perform correctly.

Equipment used with the rope

Pulleys and other equipment that you use with your rope, are actually meant for a specific diameter size and type of rope. For example, pulleys that are designed for wire rope have a different type of groove in the sheave than those designed for synthetic and fibre ropes.

Maintenance

Always check the manufactures guidelines for how to best maintain your rope. As a general rule, when not in use, make sure to store rope in a well ventilated and dry area. Keep exposure to UV, dust, water, chemicals and climatic conditions to a minimum. Maintenance of wire rope should include occasional application of a lubricant such as a heavy duty liquid lanolin. Also make sure to take care in handling to avoid creating kinks and crushed sections of rope.

Heat and UV

Wire rope is much more resistant to heat than synthetic. Synthetic winchline, depending on the brand starts softening around 140°C and melts at 152°C . This is just an example of one brand, and all ropes will react differently. A good quality synthetic winchline will be UV resistant but left out in the strong Australian sun, will still deteriorate over time from the UV exposure.

Sizes

Your winch drum is designed to take a specific diameter and length of rope. Always check with the manufacturer if changing the rope. Both types of rope are available in a wide range of sizes and working loads. Synthetcic rope is available in a number of different colours as well.

Price

There is a large price difference between wire rope and synthetic winchline. Synthetic winchline is around double the cost of wire rope.

Breaking force

Synthetic rope is 70% stronger than the same size wire rope. Another myth we came across, is if synthetic winch line breaks it just falls to the ground. If a winchline breaks it’s generally going to be at the worst possible time, when there is a load on the end of the line. When synthetic rope snaps it will still go flying but with a lot less force than wire rope.

Well, what’s better?

As you’ve read, it really depends on what you’re doing. Both ropes have pros and cons and at the end of the day it’s what's going to work best for you and your application.

Visit our online store to check out our range of wire rope (and accessories) and synthetic rope. Can’t find what you’re looking for on our website? We can source it for you. Contact us online today or phone 1300 666 733.